Gold Ore Processing Mobile Hydraulic Crusher

Working Principle

HCC series single cylinder hydraulic cone crusher, a kind of cone crusher with advanced technology in the world, has not only the features of high reliability, but also the feature of high crushing efficiency, low operation cost, and good shape of the end products. It is widely used in mining and gravel aggregate industries, and is suitable for crushing various materials with hard and above medium hardness.

There're various options for cavities. By proper chamber and eccentricity, it meets the customer's maximum demand for production and high output. Under the condition of full feeding, it can realize laminating crushing, and make better material for the products.

Low Vulnerable Part Consumption and Low Operation Cost

The discharge opening can be adjusted timely and conveniently with hydraulic adjusting design, which realizes full load operation, lower wear parts consumption and reduces operation cost.

Easy Chamber Exchange

Due to the same body structure, we can get different crushing chamber by changing the liner plate to fulfill the various processing requirement for primary and fine crushing.

Advanced Hydraulic Technology Offers Easy Operation and Maintenance

Adopting advanced hydraulic technology, the overload protection can be realized effectively, which simplifies the structure of crusher and reduces its weight. All maintenance and inspection can be fulfilled through the top of the crusher, achieving easy maintenance.

Large Feeding Inlet Design

Large feeding inlet design is adopted by S type HCC series cone crusher to provide good mating with primary jaw crusher and the crushing capacity can be greatly increased. While processing gravels, it can replace jaw crusher for primary crushing.

Application Scope

Hydraulic cone crusher is one of the most commonly used mining equipment, which is widely used in mineral processing, construction materials, silicate and chemical industries. In the production of small scale, medium scale or large scale mineral processing plants, it is generally used as the secondary and tertiary crushing machine to crush hard or medium hard metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, as well as stone, rock, granite, limestone, barite, quartz, graphite, feldspar, fluorspar, etc.

Technical Parameters of HCC Series Single Hydraulic Cylinder Cone Crusher

Technical Parameters of Medium Crushing Type

1. What is the main business scope of your company?

HZE is a company with R&D center, design institute, manufacturing factories, installation and commissioning teams. Our customers are in the mining and mineral processing fields. Our major businesses include mineral processing EPC (engineering, procurement and construction), project consultation, engineering design, mineral processing equipment manufacturing, on-site installation, commissioning, staff training, customer project operation management, spare parts supply and technical support. Customers are free to choose any one or any combination of our services.

2. What are the outstanding advantages of your company?

The one-stop service of mineral processing engineering project and equipment is our core competitiveness.

The most important feature that HZE distinguishes itself from other engineering companies, design companies or consulting companies is that we are also an equipment manufacturer with a production plant of 50,000 square meters, and we have complete manufacturing rout and the related equipment.

HZE distinguishes itself from other equipment manufacturers by owning its own R&D center and engineering design institute.

HZE distinguishes itself from many mining machinery enterprises by possessing an expert team with members including not only senior engineers of the company, but also top Chinese technical experts, university professors and researchers.

3. What are the characteristics of your company's 3D design?

HZE not only uses 3D software to design equipment, but also uses 3D software to design process flow, pipeline, steel structure, auxiliary facilities, etc. of the whole mineral processing project. We even use 3D design for equipment packaging, container packing and equipment instructions manual. This greatly improves the quality of equipment and engineering, shortens the construction period, facilitates technical discussion and evaluation, facilitates project management, improves construction safety and reduces project cost.

4. What are the service features of your company?

Working Principle

HCC series single cylinder hydraulic cone crusher, a kind of cone crusher with advanced technology in the world, has not only the features of high reliability, but also the feature of high crushing efficiency, low operation cost, and good shape of the end products. It is widely used in mining and gravel aggregate industries, and is suitable for crushing various materials with hard and above medium hardness.

There're various options for cavities. By proper chamber and eccentricity, it meets the customer's maximum demand for production and high output. Under the condition of full feeding, it can realize laminating crushing, and make better material for the products.

Low Vulnerable Part Consumption and Low Operation Cost

The discharge opening can be adjusted timely and conveniently with hydraulic adjusting design, which realizes full load operation, lower wear parts consumption and reduces operation cost.

Easy Chamber Exchange

Due to the same body structure, we can get different crushing chamber by changing the liner plate to fulfill the various processing requirement for primary and fine crushing.

Advanced Hydraulic Technology Offers Easy Operation and Maintenance

Adopting advanced hydraulic technology, the overload protection can be realized effectively, which simplifies the structure of crusher and reduces its weight. All maintenance and inspection can be fulfilled through the top of the crusher, achieving easy maintenance.

Large Feeding Inlet Design

Large feeding inlet design is adopted by S type HCC series cone crusher to provide good mating with primary jaw crusher and the crushing capacity can be greatly increased. While processing gravels, it can replace jaw crusher for primary crushing.

Application Scope

Hydraulic cone crusher is one of the most commonly used mining equipment, which is widely used in mineral processing, construction materials, silicate and chemical industries. In the production of small scale, medium scale or large scale mineral processing plants, it is generally used as the secondary and tertiary crushing machine to crush hard or medium hard metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, as well as stone, rock, granite, limestone, barite, quartz, graphite, feldspar, fluorspar, etc.

Technical Parameters of HCC Series Single Hydraulic Cylinder Cone Crusher

| Model | Chamber | Inlet Size (mm) | Max. Feeding Size (mm) | Discharging Size (mm) | Power (kW) | ||

| HCC100 | Stroke 16 | Stroke 22 | 90 | ||||

| A | 150 | 120 | 12~39 | 15~37 | |||

| B | 130 | 105 | 10~33 | 11~31 | |||

| C | 100 | 85 | 7~33 | 9~30 | |||

| D | 40 | 32 | 5~31 | 6~29 | |||

| HCC200 | Stroke 18 | Stroke 25 | 160 | ||||

| A | 220 | 180 | 18~35 | 22~30 | |||

| B | 150 | 120 | 15~35 | 19~30 | |||

| C | 80 | 60 | 9~35 | 12~30 | |||

| D | 40 | 32 | 6~35 | 8~30 | |||

| HCC300 | Stroke 25 | Stroke 32 | 250 | ||||

| A | 230 | 190 | 20~45 | 25~40 | |||

| B | 150 | 125 | 17~45 | 20~40 | |||

| C | 80 | 60 | 10~40 | 13~35 | |||

| D | 40 | 32 | 6~40 | 8~35 | |||

| HCC500 | Stroke 25 | Stroke 32 | Stroke 40 | 315 | |||

| A | 230 | 180 | 22~50 | 26~45 | 30~40 | ||

| B | 150 | 125 | 19~48 | 22~43 | 26~38 | ||

| C | 100 | 80 | 12~40 | 14~35 | 16~30 | ||

| D | 50 | 40 | 8~30 | 10~25 | 12~20 | ||

| Model | Stroke | Closed Side Discharge Outlet (mm) | ||||||||

| 8 | 12 | 16 | 20 | 25 | 30 | 35 | 40 | 45 | ||

| Capacity (t/h) | ||||||||||

| HCC100 | 16 | 35~40 | 45~55 | 55~65 | 67~75 | 75~85 | 90~100 | 105~115 | ||

| 22 | 45~50 | 55~65 | 65~75 | 75~90 | 85~105 | 100~125 | 115~135 | |||

| HCC200 | 18 | 65~75 | 75~90 | 85~105 | 100~125 | 135~150 | 160~175 | 170~190 | ||

| 25 | 90~110 | 110~130 | 125~155 | 160~180 | 185~210 | |||||

| HCC300 | 25 | 100~120 | 110~135 | 130~160 | 150~180 | 170~200 | 200~230 | 230~260 | 250~290 | 270~310 |

| 32 | 110~135 | 130~150 | 160~200 | 180~220 | 200~250 | 230~280 | 260~310 | 280~320 | 300~340 | |

| HCC500 | 25 | 100~120 | 120~150 | 140~170 | 160~190 | 190~220 | 220~250 | 250~280 | 280~310 | 330~370 |

| 32 | 150~170 | 170~200 | 200~230 | 250~270 | 280~300 | 310~340 | 370~420 | 430~500 | ||

| 40 | 180~200 | 210~240 | 250~280 | 300~330 | 330~380 | 370~420 | 430~500 | |||

Technical Parameters of Medium Crushing Type

| Model | Chamber | Inlet Size (mm) | Max. Feeding Size (mm) | Discharging Size (mm) | Power (kW) | ||

| HCCZ100 | Stroke 16 | Stroke 22 | 75~90 | ||||

| A | 250 | 210 | 35~65 | 35~60 | |||

| B | 200 | 170 | 35~65 | 35~60 | |||

| HCCZ200 | Stroke 18 | Stroke 25 | 110~160 | ||||

| A | 330 | 280 | 27~65 | 30~60 | |||

| B | 250 | 210 | 25~60 | 28~55 | |||

| HCCZ300 | Stroke 25 | Stroke 32 | 160~250 | ||||

| A | 380 | 320 | 28~73 | 32~69 | |||

| B | 280 | 240 | 26~66 | 30~62 | |||

| HCCZ500 | Stroke 18 | Stroke 25 | Stroke 32 | 250~315 | |||

| A | 500 | 420 | 50~80 | 55~75 | 60~70 | ||

| B | 380 | 320 | 40~70 | 45~65 | 50~60 | ||

| Model | Stroke | Closed Side Discharge Outlet (mm) | ||||||||

| 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | ||

| Capacity (t/h) | ||||||||||

| HCCZ100 | 16 | 135~150 | 145~165 | 155~175 | 165~185 | 175~190 | 180~205 | |||

| 20 | 160~180 | 170~200 | 180~210 | 190~220 | 200~230 | 205~235 | ||||

| HCCZ200 | 18 | 160~190 | 180~210 | 200~230 | 230~250 | 250~270 | 270~300 | |||

| 25 | 190~240 | 210~260 | 230~280 | 260~310 | 290~340 | 310~370 | ||||

| HCCZ300 | 25 | 250~300 | 290~340 | 320~350 | 350~380 | 380~410 | 410~440 | 440~470 | ||

| 32 | 340~390 | 370~420 | 400~440 | 430~470 | 470~500 | 500~510 | 530~540 | |||

| HCCZ500 | 18 | 300~350 | 330~380 | 370~420 | 400~450 | 430~480 | 460~510 | 500~550 | ||

| 25 | 500~550 | 550~600 | 600~650 | 650~700 | 700~750 | 750~800 | ||||

| 32 | 650~700 | 700~750 | 750~800 | 825~875 | 900~950 | 950~1000 | ||||

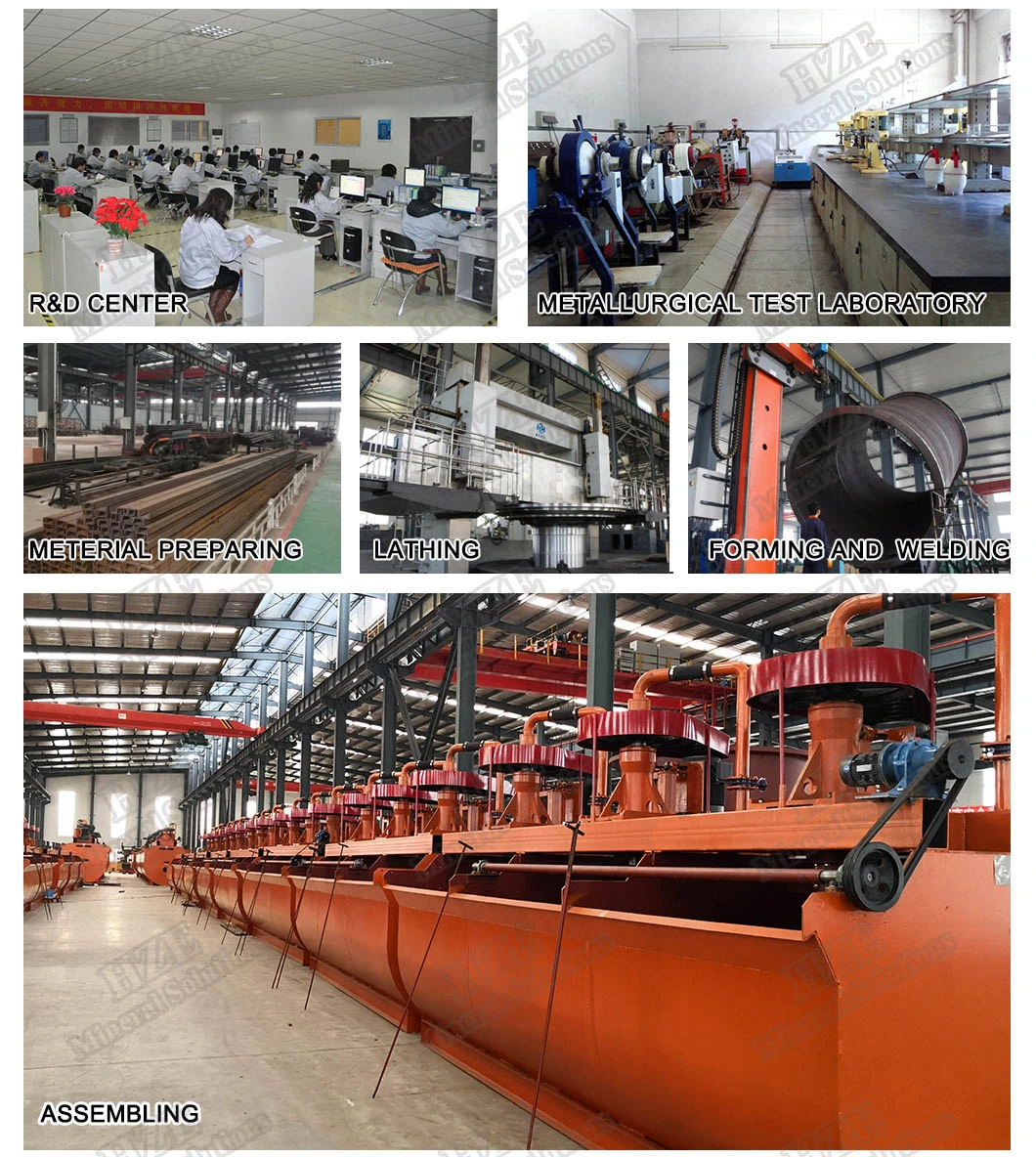

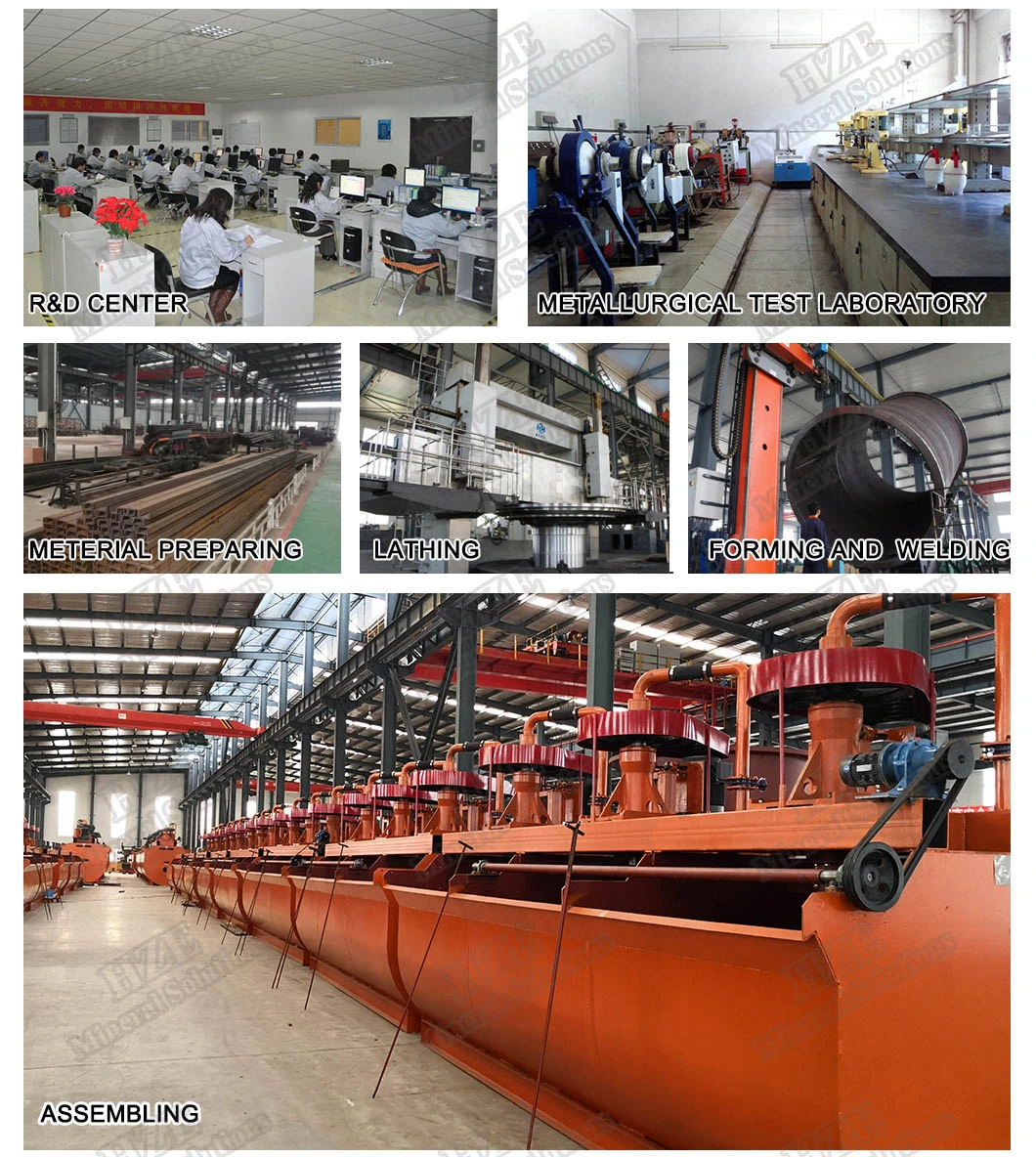

1. What is the main business scope of your company?

HZE is a company with R&D center, design institute, manufacturing factories, installation and commissioning teams. Our customers are in the mining and mineral processing fields. Our major businesses include mineral processing EPC (engineering, procurement and construction), project consultation, engineering design, mineral processing equipment manufacturing, on-site installation, commissioning, staff training, customer project operation management, spare parts supply and technical support. Customers are free to choose any one or any combination of our services.

2. What are the outstanding advantages of your company?

The one-stop service of mineral processing engineering project and equipment is our core competitiveness.

The most important feature that HZE distinguishes itself from other engineering companies, design companies or consulting companies is that we are also an equipment manufacturer with a production plant of 50,000 square meters, and we have complete manufacturing rout and the related equipment.

HZE distinguishes itself from other equipment manufacturers by owning its own R&D center and engineering design institute.

HZE distinguishes itself from many mining machinery enterprises by possessing an expert team with members including not only senior engineers of the company, but also top Chinese technical experts, university professors and researchers.

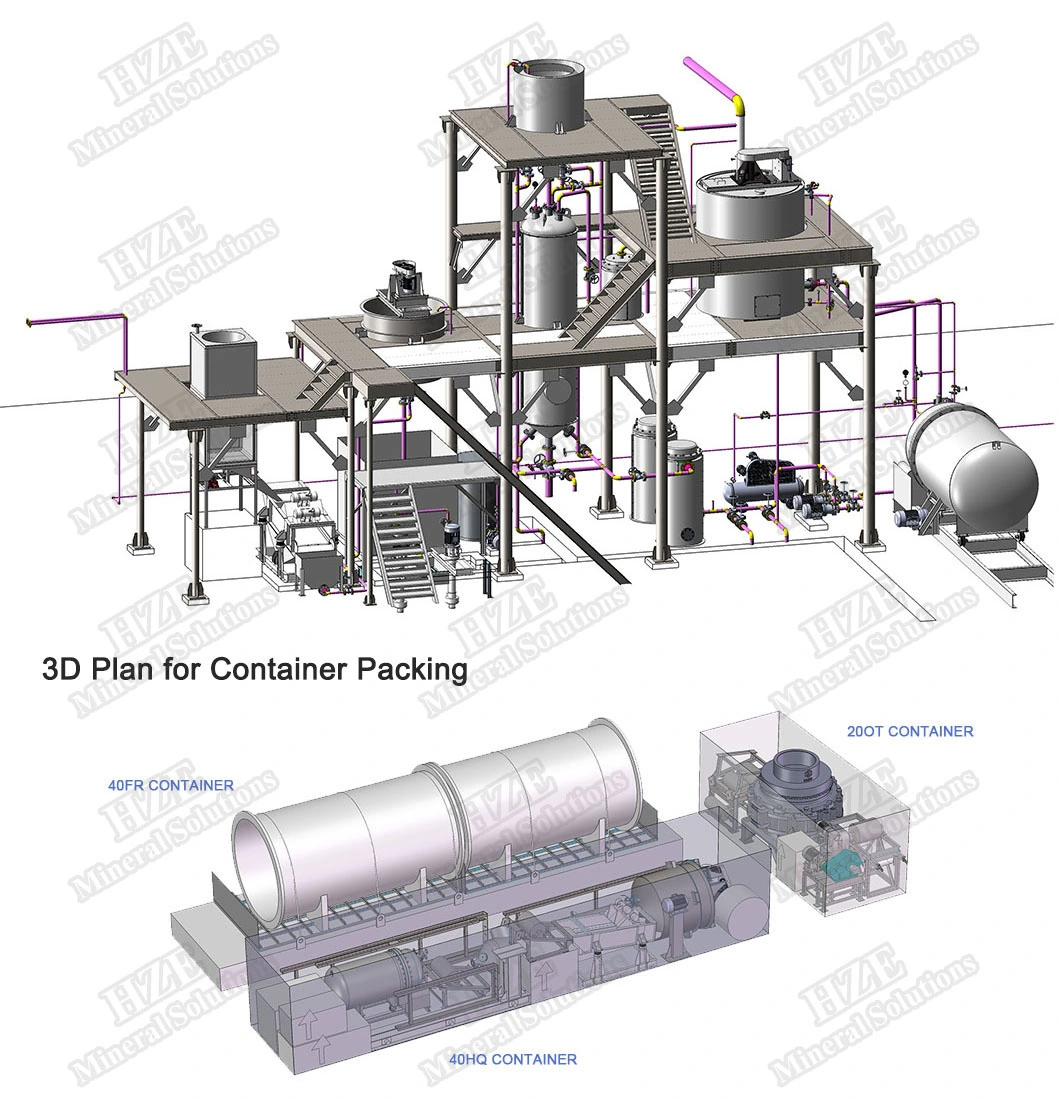

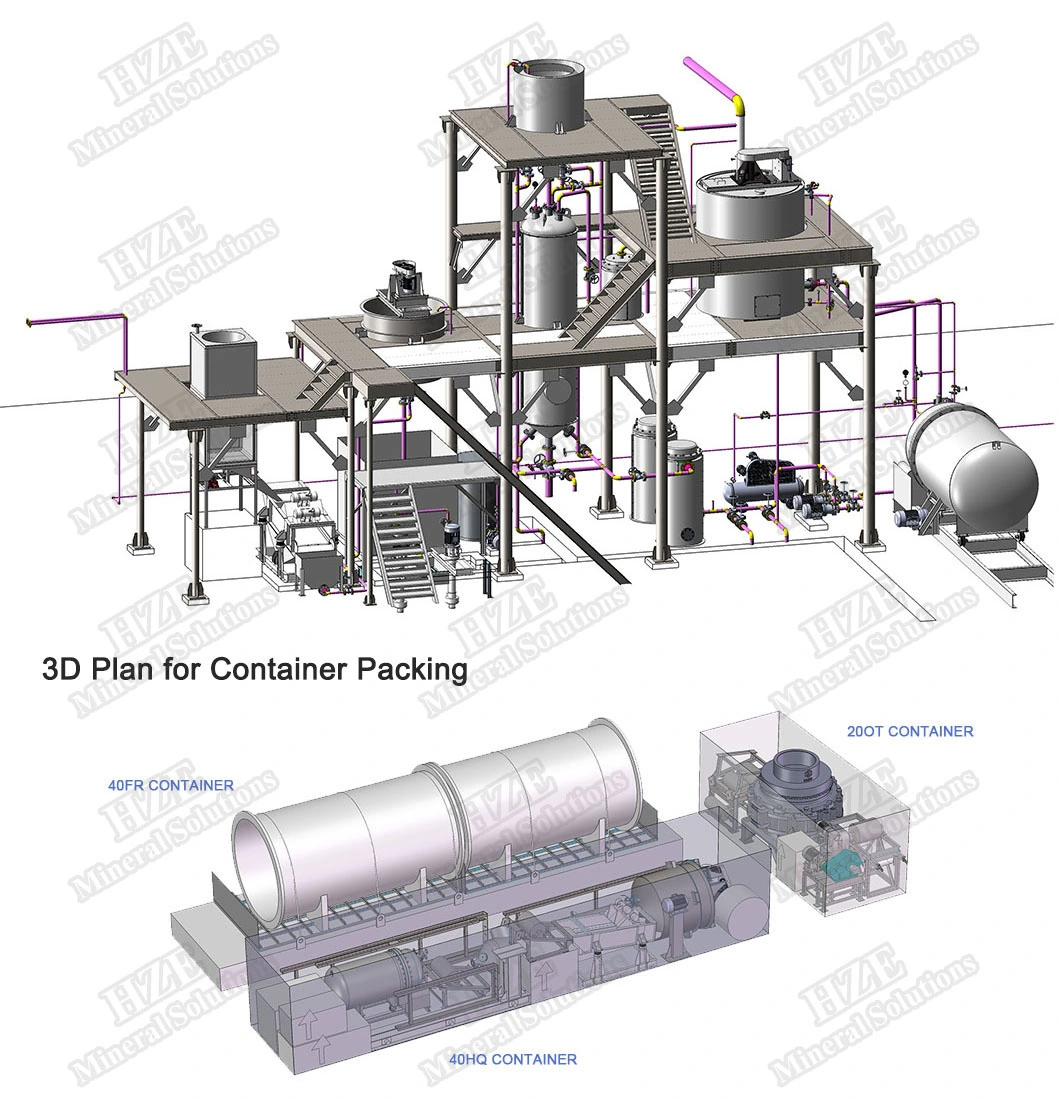

3. What are the characteristics of your company's 3D design?

HZE not only uses 3D software to design equipment, but also uses 3D software to design process flow, pipeline, steel structure, auxiliary facilities, etc. of the whole mineral processing project. We even use 3D design for equipment packaging, container packing and equipment instructions manual. This greatly improves the quality of equipment and engineering, shortens the construction period, facilitates technical discussion and evaluation, facilitates project management, improves construction safety and reduces project cost.

4. What are the service features of your company?

- Customers who whether buy our equipment, or entrust us with EPC, or require us to provide a certain service, cooperate closely with us to carry out specific operations and supervise our implementation throughout the process.

- HZE will try to understand the basic situation and needs of customers as detailed as possible before the sale, formulate a preliminary plan according to the specific situation of customers, and get unanimous opinions after communications and discussions with customers to determine the plan.

- We set up customer files for every customer who signed the contract with us and upload them to the Cloud where customers can also get an account and password. Customers can have all the documents, videos and pictures, technology, services, execution, operation, management and control, maintenance and so on related to the business.

- Whether it is in the process of general contracting, equipment manufacturing or providing some kind of service, we welcome customers to know about our implementation on the spot or through the network, and put forward requirements and opinions.

- We assist users who have used our products to formulate operation specifications and make suggestions on maintenance plans and spare parts inventories. In addition to routine on-site installation, commissioning and training, during the production period after we handing over equipment to customers for use, we often understand the equipment using situations through the network and provide guidance and training to customer management and operators.

- For the clients who have just start the mining business, we provide the opportunity of training and practice in China's mines for the clients' employees, until they are skilled in operation and maintenance.